Woodworkers and DIY enthusiasts are aware that the choice of materials can be the difference between a successful or unsuccessful project. Solid wood is a timeless product, but engineered wood products such as MDF (Medium Density Fiberboard), melamine and particle boards are a great alternative. Understanding the specific properties of each product and capabilities is the key to achieving beautiful and functional results.

MDF Board: The Champion of Smoothness and Adaptability

MDF boards are common for woodworking shops all over the world. Their smooth and uniform surface is easy to work with, and is capable of taking stain, paint and even veneers. MDF is more solid than solid wood. It does not crack or warp. The predictable nature of MDF is ideal for intricate carvings and moldings.

The Benefits of Using MDF Boards:

A professional-looking finish is achieved by the smooth surface, which permits flawless paint and veneer applications.

Working ability: MDF board is easy to cut, drill, and drill and. This makes it ideal for intricate designs.

MDF Boards are tough and Durable: MDF boards of high quality can withstand the rigors of damage and water despite their appearance.

MDF boards can be used in a variety of ways. They can be used to make cabinets, furniture and even architectural components.

Melamine Sheets where durability meets fashion

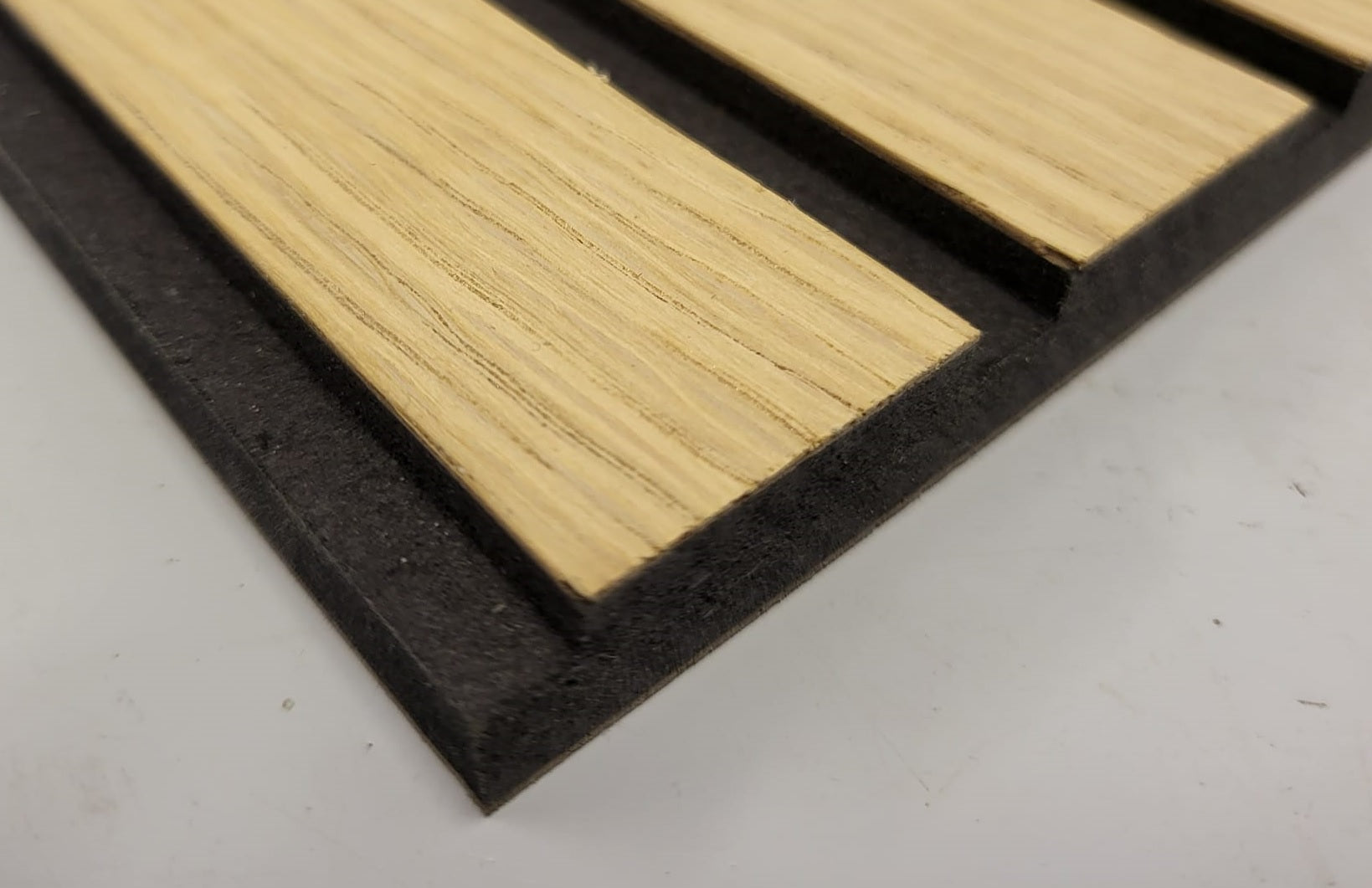

Melamine sheets are a beautiful accent to MDF boards. They are made of a thin layer of melamine resin that is joined to MDF and creates an attractive and durable surface. Melamine finishes can be found in many styles, colors, patterns and textures.

The Advantages of Melamine Sheets

Scratch and stain resistant: The melamine surface provides an unbeatable level of resistance against stains and scratches. They are great for areas that see lots of traffic, like kitchens and bathrooms.

Easy Maintenance: Melamine sheets require minimal upkeep. They can be kept looking new with a simple wipe down using a damp towel.

Cost-effective alternative: Compared to solid wood that has similar aesthetics, melamine sheets can be an economical alternative with a premium appearance.

A wide range of applications from kitchen cabinetry and countertops to wall panels and furniture, the range of applications for Melamine sheets is what makes them an ideal choice for both residential and commercial projects.

Particle Boards: A Economic Alternative

Particle board, although a less popular choice compared to MDF and melamine is an affordable solution for projects where structural integrity is required to take precedence over aesthetics. Made from compressed wood particles, and then bonded with resin, this board can provide a reasonable level of robustness and stability.

Understanding Particle Board:

Cost-Effective: Particle board is the most affordable option among the three mentioned.

Limited Applications: Due to its rougher surface and lower water resistance, the particle board is ideal for areas where aesthetics aren’t the primary concern, such as internal furniture parts or subflooring.

The particle board can expand and lose its strength when exposed to moisture. It’s important to select products that resist moisture in humid environments.

Selecting the Best Engineered Wood Panel

The engineered wood panels that you select will depend on the needs and priorities of your project. Here’s a quick guide to help you make a decision:

MDF boards offer a smooth surface along with intricate designs, and they are flexible.

Melamine sheets provide the greatest combination of scratch resistance, durability, and pre-finished surfaces.

If you’re looking for a cost-effective option, however structural stability is your main concern Particle board might be the best option.

The Future of Woodworking: Embracing Engineered Wood Options

MDF sheets, melamine sheets, and particle board are all excellent options for DIYers as well as woodworkers. Their cost-effectiveness, flexibility and consistency makes them an essential part of the toolbox of any project. It is likely that we will see more and more unique engineered solutions appear as technology develops. This will also expand the creativity of the future for woodworking.