Innovation is the heartbeat for the medical device industry. To bring new ideas into reality, you need an experienced partner who can help you transform ideas into prototypes, and then, eventually, production parts that are of the highest quality. Influx Labs is a reliable partner that can translate concepts into prototypes and ultimately, high-quality parts for production.

Influx Labs facilitates medical device invention from idea to prototype

The path of medical device companies from concept to the moment it is launched on the market is not easy. Influx Labs understands the importance of effective prototype manufacturing in this process. Influx Labs offers a welcoming atmosphere for turning innovative ideas into testable, prototypes. This allows you to modify designs and obtain important feedback prior to investing in large-scale manufacturing.

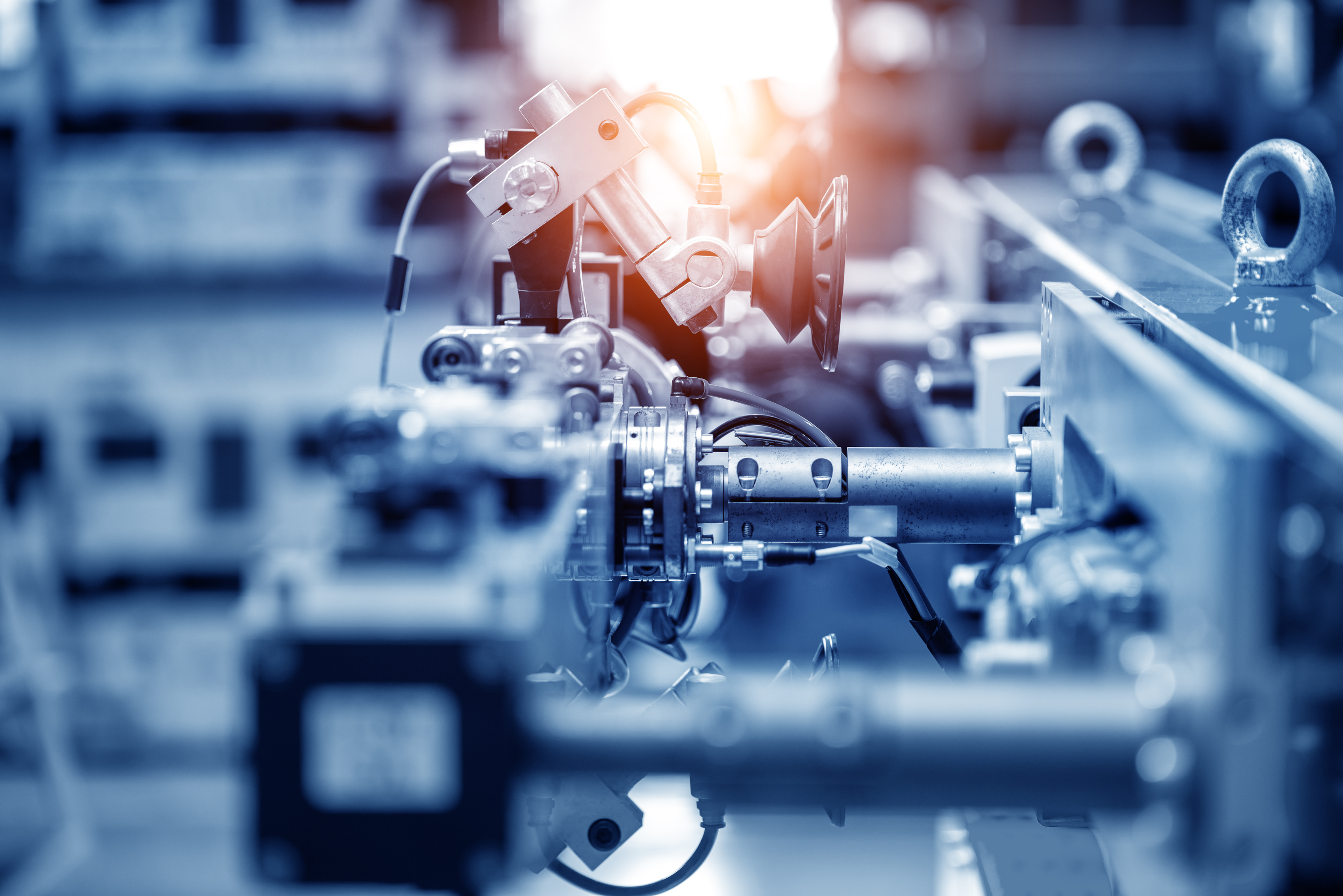

Influx Labs CNC Machining Expertise: The Power of Precision

At the core of Influx Labs’ capabilities lies their state-of-the-art CNC cutting-edge technology. Computer Numerical Control machining (CNC) utilizes computer-aided instruction to precisely control the cutting tool, allowing highly precise and intricate components. This technology allows Influx Labs to craft medical device prototypes and production parts that conform to the strictest standards for medical devices.

Beyond Prototyping: Scaling Up Production

Influx Labs services go beyond rapid prototypes. Their expertise in CNC-machining permits the seamless transition from prototyping to high volume production runs. This reduces the need to find a separate manufacturing partner and streamlines the entire process and guaranteeing that the prototype is identical to the final product.

Affirmed Commitment to Quality Materials Trackability and Certifications

Influx Labs understands the importance of quality for the medical device industry. Influx Labs has a process which ensures complete material tracking throughout the entire manufacturing process. This will ensure that you have full transparency regarding the materials used in the creation of prototypes and components. Furthermore, Influx Labs can provide materials and finishing certificates upon demand, providing you with peace of mind while meeting stringent regulatory requirements.

Why should you choose Influx Labs to meet your medical device needs?

Influx Labs stands out from other companies for prototypes and machining due to a number of factors. Influx Labs is a valuable partner for your medical device design:

Dedicated to Medical Devices: Influx Labs is aware of the particular demands in the field of medical devices. They have the expertise and know-how required to manufacture medical-grade components that are of the highest quality.

Precision Engineering: Advanced CNC processing capabilities guarantee consistent results and unmatched accuracy that are essential for making reliable and functional equipment.

Influx Labs is a one-stop-shop for prototyping and production. This helps you save the time and effort of searching for several suppliers.

Commitment to Quality: From material traceability to certifications Influx Labs prioritizes quality control and ensures that your medical devices comply with the highest standards.

Influx Labs accelerates your medical device development process

Influx Labs is a leader in the field of prototype manufacturing, CNC machining and development of medical devices. This experience lets companies develop new products faster and more efficiently. Influx Labs can provide you with:

Lower risk: Prototyping helps you identify potential problems early on during the development process, minimising risks associated with large-scale production.

Influx Labs’ streamlined prototyping and production lets you get your medical device quicker to market.

Enhanced Design Refinement: Physical prototypes allow extensive testing and feedback from users, allowing you to refine your design with more confidence.

Influx Labs can help you unlock the potential of rapid prototypes as well as precision CNC machines. Follow along as your ideas for medical devices become real and shape the future of healthcare.